If you want to know more information about our machine, please sent email to Zhengzhouyuxi@yuximachine.com, we will give you the most professional reply at first time!

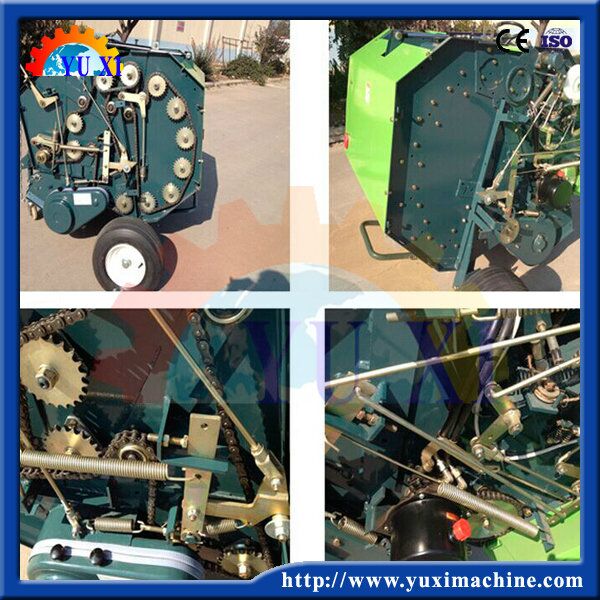

Mini Hay Bale Introduction

Mini hay baler, also known as mini round baler, is mainly used for picking up straw and packing hay, wheat straw, corn straw, etc., which is convenient for transportation, storage and deep processing. Miniature hay baler can work in farm and pasture, it also can adjust the length and density depending on the requires of the raw material.

Mini Hay Bale Standard features

• Self-contained hydraulics. All hydraulic functions are contained within the mini square baler. The operator controls the baler functions with a simple electronic control box, magnetically attached to the tractor.

• Gathering wheels. The pinwheels mounted on either side of the small round hay baler increase its width so that you can bale larger windrows without missing any hay.

• Close spacing of pickup tines and rollers. With a much closer spacing, less hay is missed in the pickup process, and the hay is better contained in the compact hay baler chamber with smaller, more closely spaced rollers.

• Lateral drawbar connection. A drawbar is easier to connect than 3 point connection, and the ability to work with the machine out to the side makes monitor baling progress less fatiguing.

• Automated pickup control. Mini round baler machine, allows you to adjust the pickup height from the tractor seat, which will simplify fine tuning of your baling process in changing field conditions.

Mini Hay Bale Benefits

√ Requires only a 30hp tractor;

√ Lower initial equipment investment;

√ Dry bales are easily rolled in a barn or loft;

√ Less labor than small square bales;

√ Higher potential profit per ton;

√ Make the picking and bundling up at one time;

√ Easy to transport and storage after strapping;

√ Small volume, light weight, compact structure, easy to operate;

√ Can be followed in combine harvester to achieve the best effect, save time and effort.

Mini Hay Bale Working Principle

The raw material is rolled up inside the miniature square baler by using rubberized belts, fixed rollers, or a combination of the two. When the bale reaches a certain size, either netting or twine is wrapped around it to hold its shape. The back of the compact hay baler swings open and then the bale is discharged. The bales are complete at this stage, but they may also be wrapped in plastic sheeting by wrapper of the baler, which can keep hay dry when stored outside, or convert damp grass into silage.

Technical Parameters

Name Parameters Motive power 5.5-11kw Bundle size Φ550 * 520mm Diesel ≥12-20 Production efficiency 60-65 bales / h 5-6t / h Dimensions 2135 * 1350 * 1300mm Bale weight 65-100kg / bundle Weight 510kg Bale density 450-500kg / m³ Twine consumption 2.5kg / t Envelope machine power 1.1-3kw Production efficiency 13/19 seconds