Wood pellet production line

Wood pellet production line

If you want to know more information about our machine , please sent email to zhengzhouyuxi@yuximachine.com, we will give you the most professional reply at first time !

Brief Introduction Of whole Wood Pellet Production Line

Wood pellet production line refers to a complete process for making biomass material into a new type environmental protection pellets widely used as bio-fuel for industrial and commercial use. We are professional wood pellet line supplier with more than 20 years history and can make perfect design according to your workshop and your different raw materials with the economical capital investment.

The materials can be sawdust, rice husk, cotton stalk, cottonseed skins, weeds and crop stalks and other plant wastes, especially low-bonding and unformed materials.

.jpg) |

Advantage and suitable condition of raw material

1- 1-Wide range, so it is easy to collect. It will save your cost.

2-Biomass material belong to one kind natural energy. It has no damage for the environment.

3-Biomass material includes lignin, it is one kind natural binder. And it will released out and formed into good quality pellets with the machine temperature. So you don't need to add any additive any more.

4-Market has a large demand for energy product. So the pellets market is developing larger and larger.

2-Biomass material belong to one kind natural energy. It has no damage for the environment.

3-Biomass material includes lignin, it is one kind natural binder. And it will released out and formed into good quality pellets with the machine temperature. So you don't need to add any additive any more.

4-Market has a large demand for energy product. So the pellets market is developing larger and larger.

2- 1-Suitable size: less than 3-5mm

2-Moisture content: 12-20%

3-Raw materials can be the mixture of 2 or more than 2 kinds different materials, they must be evenly mixed.

4-The production processing does not need any adhensive or chemicals.

General Description Of Whole Processing

The whole line includes mainly many machines, not all of the machine is necessary. You can choose the machine from the machines.

Crushing Process—Drying Process—Pellet Making Process—Cooling and Screening Process—Packing Process

Step 1: Crusher-- It is used to crush the raw materials into sawdust, with the suitable size 3-5mm before the raw materials enter into the pellet machine.

Step2: Screw conveyor --It is used to transfer the crushed powders to the dryer. It can save the man power and improve the working efficiency at the same time.

Step 3: Dryer--If the moisture of the powder is more than 12%. Then you can use this drying machine. You also can choose to dry the sawdust naturally.

Step 4: Screw conveyor--It is used to transfer the crushed and dried powder to the pellet machine. You can also use man power instead of this machine.

Step 5: Pellet machine--It is used to make the powder into pellets. The diameter of final pellets can be adjustable based on the customers’ requirement.

Step 6: Cooler—It is used to reduce the temperature of final pellets, screen the good pellet as well, then you can get the pure pellets and pack them directly.

Step7: Packing machine—It covers 4 parts, the lifting part, belt conveyor, weighting part, sealing part, It is used to pack the final pellets into bags in a certain amount.

The Features of Whole Pellet Production Line

1. High capacity and quality of the whole line, we provide the professional design before you start the production and effective after-sale service. 24 hours on line support is always ready to serve you.

2. Famous brands electric motor for the machine, it can make sure the continues working and extend the service life of the machine.

3. Competitive price with good performance, long term supply of machine from our factory directly with CE, SGS, ISO certification.

4. Full automatic of whole line by the power cabinet, it is much more convenient for the operators, and can save the man power highly and increase the working efficiency as well.

5. We insist on "Quality is the soul of company" .Our professional service includes: Free training, Guidance Installation and Debugging.

Final pellets

Usage: for animal feed pellets or fuel pellets

Diameter: 2.5-10 mm

Length: can be adjustable

Shape: cylinder

Feature of fuel pellets: high density, high heating value, easy to burn, long burning time as well

|

Reference questions of wood pellet production line

If you're interested in our machines, please don't hesitate to list :

1. what’s the raw material you will use for the pellet production, as well as for the size and moisture content ?

2. output capacity per hour you need ?

3. your local voltage

3. your local voltage

Welcome to visit us

Our company introduces advanced technology at home and abroad. By continuous improvement and innovation, we successfully invent flat die series pellet making machine, which are specially fit for biomass, fertilizer pellets and animal feed making, meeting the international demand of renewable compression biomass energy market and feed market.

If you have some free time, it is better that you can arrange a short visit to our factory, to see and test the machine on the scene. All your concerns will be received our careful attention and prompt reply. Any questions, we can discuss further and deal with together.

Our service

1. MOQ: 1 set

2. Delivery time: Within 15 working days after receiving your prepayment

3. Warranty time: in 12 months except for spare parts

4. Documents: sale contrast, packing list, insurance policy, commercial invoice

4. Our professional service includes: free training, guidance, installation, and debugging.

5. After selling, we provide the warranty of one year

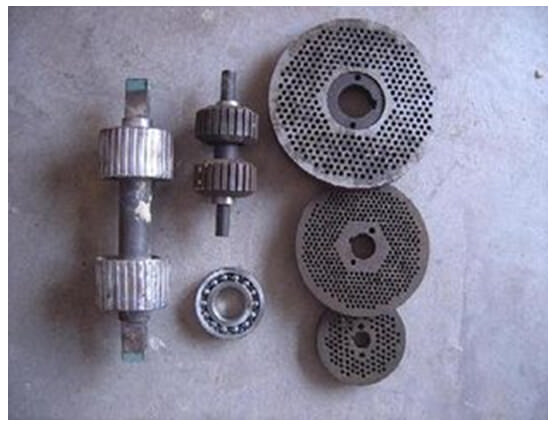

Main spare parts

The main spare of wood pellet machine, roller and die. They are made by 40Cr, which has the good abrasive

resistance. It is also can extend its service life of the spare parts.

|

Shipment

Delivery by sea

Packing

Inner packing: stretch film

Outside package: plywood case