Pro-environmentGasification type carbide furnace

Pro-environmentGasification type carbide furnace

Pro-environmentGasification type carbide furnace:

If you want to know more information about our machine , please sent email to zhengzhouyuxi@yuximachine.com, we will give you the most professional reply at first time !

.jpg) |

Product introduction:

This machine can carry out continuous production by combustible gas once lit gasification furnace produced, with energy saving, environmental protection, efficient advantage.

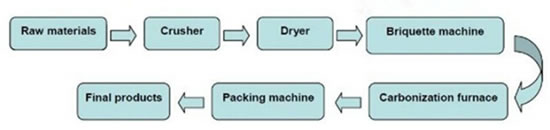

Working principle

First ignite the fuel in the gasifier (such as sawdust, wood scraps, etc.) , flue gas produced by combustion after in the pipeline, which is through spraying, cooling, cleaning process, the combustible gas generated (carbon monoxide, methane, ethane, etc.) as heat source of pre carbonization, of raw materials on the combination of two or three furnace furnace carbonization furnace in 1#, 2#, 3# and charring tank (such as mechanism of rod, logs, bark, pine cones) heating carbonization. Fume produced during the carbonization process of full recovery, by spraying, cooling, purification process, carries on two times to make the combustible gas generated by combustion. According to this cycle, generated by the combustion of autologous autologous gas, achieve the effect of saving energy. Flue gas emissions throughout the production process, meets the requirements of national environmental protection.

Technical parameters

During the production process, the coking in furnace temperature of 260 ℃ to 600 ℃ when the normal coking, the highest temperature can reach 800 ℃ to 900 ℃.Temperature could be regulated and controlled by control cabinet.

Performance characteristics:

According to different raw materials, every 4 hours can be two or three cans of finished product carbon (about 500 kg/tin).This production line can work continuously 24 hours a day.

|

Packaging and shapping of our machines:

1. All the machines will be wrapped up with plastic film first (including the motor).

2. The plastic film bag wrapped machine, according to the size and weight to make wooden or iron box, put machine in and fixed the box after loading. (The box material can be made as your requirements)

3. The machine parts need to be put in a fixed container, should be fixed well, lest collision and wear, or lost.

3. The machine parts need to be put in a fixed container, should be fixed well, lest collision and wear, or lost.

Our service for our customers:

♥. Pre-sale service: design and manufacture machines for you as your special requirements, provide you with project, process design, and purchase programm.

♥. On-sale service: accompany with you to look around our factory, explain the manufacture process of our machines, and check the working performance of our machines.

♥. After-sale service: engineers are available to install and debugging equipments of the whole production line, besides, commissioning and training operators on site.