Biomass briquette machine

If you want to know more information about our machine , please sent email to zhengzhouyuxi@yuximachine.com, we will give you the most professional reply at first time !

.jpg) |

Brief Introduction of Briquette Machine

The biomass briquette machine is mainly for making various kinds of agriculture waste, agro-forest into briquettes, which is easy to store and has the higher heating value, and it is also can achieve the resource recycling, protect the environment as well, etc.

Features of Our Biomass Briquette Machine

1. High capacity and performance of the machine

2. Long service life both for the machine and main spare parts

3. CE, ISO, SGS certification

4. Various shapes and diameter for your selection

5. Easy to burn , high heating value and long burning time

6. Easy to operate, maintain, replace the main spare pares

The raw material can be available

It has a wide application of various kinds of biomass raw material, such as rice husk, wood logs, wood chips, sawdust, coconut shell, corn stalks, corn cob, cotton stalks, bamboo, tobacco waste, sunflower stalks, wheat straw, etc.

The suitable condition for the raw material can be as following:

Size: less than 3-5mm

Moisture content: 12-20 %

Raw materials can be the mixture of 2 or more than 2 kinds different materials, they must be evenly mixed.

The production processing does not need any adhensive or chemicals

Final briquettes

Briquette diameter: 30, 40, 50, 60, 70, 80, 90mm

Length: can be adjustable by the automatic cutter on the machine based on your detailed requirement

.jpg) |

Main spare parts:

The main spare part of Biomass briquette machine covers 4 parts, there are the screw propeller, heating circle,wear-proof,forming mold. Just like the following picture:

The main spare part of Biomass briquette machine covers 4 parts, there are the screw propeller, heating circle,wear-proof,forming mold. Just like the following picture:

.jpg) |

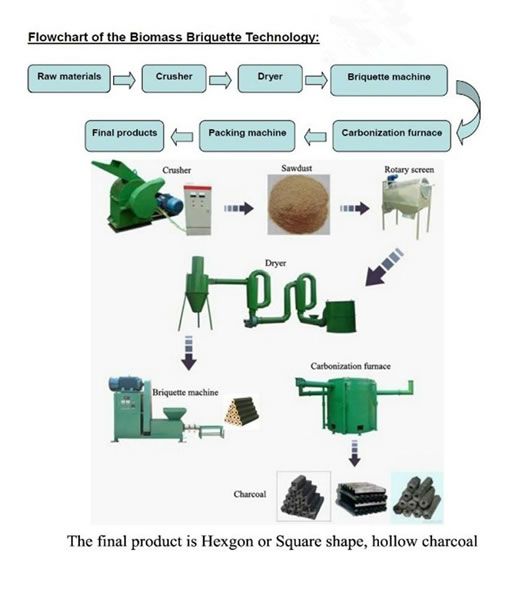

The whole process of making biomass briquettes

1. Crushing process: crush the raw material into suitable size before enter into the briquette machine, 3-5mm.

2. Drying process: reduce the moisture content of raw material to 12-20 %

3. Briquette making process: under the high pressure and temperature, the raw material will be forced into cylinder shapes by the screw propeller and heating circle.

4. Packing process: after getting the raw briquettes, you can pack them directly in order.

If you want to get the charcoal briquette, BBQ, here, you also need one carbonization furnace. 1.5t per batch for a small one and it will take about 20-30hours.