JZK70/60-4.0 Double stage vacuum extruder

If you want to know more information about our machine , please sent email to zhengzhouyuxi@yuximachine.com, we will give you the most professional reply at first time !

Clay Brick Making Machine is suitable for making the clay bricks which can be used in construction of houses, bungalows, villas, commercial and community buildings and for any place where a clay brick is required to be used. The clay bricks can be made using raw materials such as clay, black soil mixed with clay.

Clay Brick Making Machine is suitable for making the clay bricks which can be used in construction of houses, bungalows, villas, commercial and community buildings and for any place where a clay brick is required to be used. The clay bricks can be made using raw materials such as clay, black soil mixed with clay.

.jpg) |

The whole producing line of vacuum clay brick making machine :

Clay--Box feeder ---Belt conveyor----Double shaft mixer---Belt conveyor--series Double stage vacuum extruder (can be chosen according to your annual capacity)--- Full-automatic brick cutting machine -Automatic unloader(brick separator, or brick stacking machine )-Hoffman kiln or tunnel kiln

Clay--Box feeder ---Belt conveyor----Double shaft mixer---Belt conveyor--series Double stage vacuum extruder (can be chosen according to your annual capacity)--- Full-automatic brick cutting machine -Automatic unloader(brick separator, or brick stacking machine )-Hoffman kiln or tunnel kiln

.jpg) |

1. The main frames of the machine are welded by using high-quality steel, equipped with adjustable gate double extruder mouth, the actual output of up to 20,000blocks/hour or more.

2. Reamer group according to the reverse variable pitch arrangment, with “zero pressure converying, high pressure extrusion”.

3. Upper/lower bearing lubricated by thin oil, which ensure the lubrication and play the sealing effection, prolong the service life of the bearing.

2. Reamer group according to the reverse variable pitch arrangment, with “zero pressure converying, high pressure extrusion”.

3. Upper/lower bearing lubricated by thin oil, which ensure the lubrication and play the sealing effection, prolong the service life of the bearing.

.jpg) |

JZK 70 Vacuum Extruder is introduced from foreign countries . The performance of the speed reducer of the extruder is improved . The forming moisture of the brick is 16%-18% so the bricks are easy to bake . This type of Vacuum Extruder can meet the requirments of large production capacity and easy to operate .

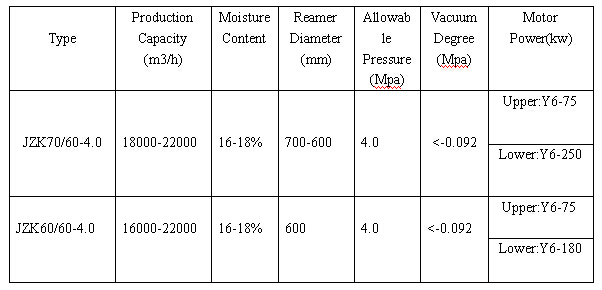

Technical Parameters :

|

|

Packaging and shapping of our machines:

1. All the machines will be wrapped up with plastic film first (including the motor).

2. The plastic film bag wrapped machine, according to the size and weight to make wooden or iron box, put machine in and fixed the box after loading. (The box material can be made as your requirements)

3. The machine parts need to be put in a fixed container, should be fixed well, lest collision and wear, or lost.

1. All the machines will be wrapped up with plastic film first (including the motor).

2. The plastic film bag wrapped machine, according to the size and weight to make wooden or iron box, put machine in and fixed the box after loading. (The box material can be made as your requirements)

3. The machine parts need to be put in a fixed container, should be fixed well, lest collision and wear, or lost.

Our service for our customers:

♥. Pre-sale service: design and manufacture machines for you as your special requirements, provide you with project, process design, and purchase programm.

♥. On-sale service: accompany with you to look around our factory, explain the manufacture process of our machines, and check the working performance of our machines.

♥. After-sale service: engineers are available to install and debugging equipments of the whole production line, besides, commissioning and training operators on site.

♥. Pre-sale service: design and manufacture machines for you as your special requirements, provide you with project, process design, and purchase programm.

♥. On-sale service: accompany with you to look around our factory, explain the manufacture process of our machines, and check the working performance of our machines.

♥. After-sale service: engineers are available to install and debugging equipments of the whole production line, besides, commissioning and training operators on site.