If you want to know more information about our machine, please sent email to zhengzhouyuxi@yuximachine.com, we will give you the most professional reply at first time!

Introduction

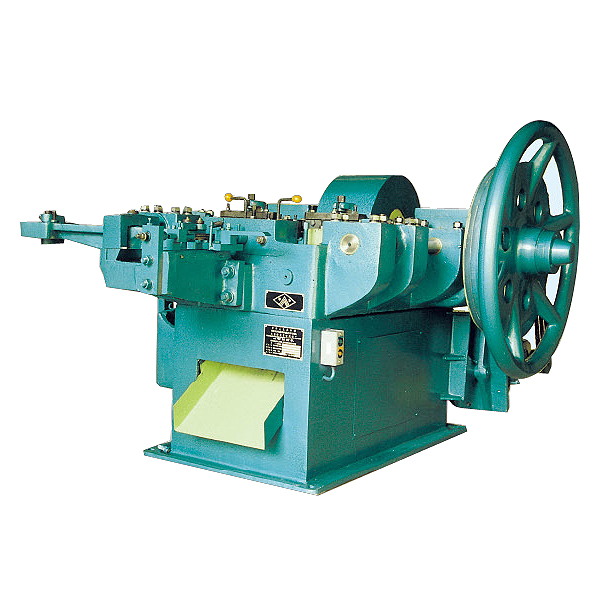

Nail making machine is used to make iron nails as a kind of production equipment.

Nail machine, also known as nail making machine equipment, scrap steel nail making machine. With point of view of turning waste into treasure, Yuxi Machine focuses on economy and practicality, the nail machine produced by us has the advantages of high technical content, easy operation, small power to save energy, stable and relible performance. The machine quality can reach standard, with features of small in size, flexible and mobile, low noise and power consumption, easy installation, etc.

Nail Making Production Process

Nail making production is divided into four parts, the most important is wire drawing.

Wire Drawing - After buying nail machine, you should firstly make sure to use new rebar, waste rebar, etc. for nailing. Waste rebar has many problems when wire drawing and has lower speed, but the cost-profit is considerable. And the wire drawing speed of new rebar is pretty fast.

Nail-making - After the wire is drawed, send the wire to wire feeding machine to produce semi-finished nails (actually the nails can be used directly to this step, but in order to get the beautiful nails, it would need one more step).

Polishing - Put semi-finished nails into polishing machine to polish. There are some common chemicals in the polishing machine, they contact with nails and polish them into shiny nails. Also can reach antirust effect.

Packaging - After completion of the above three steps, you can weigh and pack. Cartons and bags package are available according to customers’ demand.

.jpg)

Process Flow

1. Feeding

Select waste material, waste rebar, hard-drawn wire, waste welding rod or new wire rod, etc. with diameter less than 8mm, length less than 10cm as raw materials.

2. Principle

● First of all, use wire drawing machine for drawing and rust removal, get the your required specifications.

● Use nail making machine to make nail point and nail head to produce wire nail.

● Put the nails into polishing machine for polish to get needed brightness, and then pour out.

● Weigh and pack, and send out of factory.

Technical Parameters

|

Z94-1.6A |

Z94-2.8A |

Z94-3A |

Z94-4A |

A94-6A |

WZ94-6A |

||

|

Max Diameter |

mm |

1.6 |

2.8 |

3.1 |

4.5 |

6 |

3.8 |

|

Min Diameter |

mm |

0.9 |

1.2 |

1.8 |

2.8 |

4.1 |

2.38 |

|

Max Length |

mm |

25 |

50 |

75 |

100 |

150 |

100 |

|

Min Length |

mm |

9 |

16 |

30 |

50 |

80 |

50 |

|

Capacity |

No./min |

450 |

300 |

280 |

260 |

220 |

130 |

|

Motor Power |

kw |

1.5 |

2.2 |

3 |

4 |

7.5 |

4 |

|

Speed |

psc/min |

1380 |

1430 |

1430 |

1430 |

1430 |

960 |

|

Weight |

kg |

1200 |

1450 |

1600 |

1800 |

3500 |

2100 |

|

Size |

mm |

1500* |

1700* |

2000* |

2200* |

3200* |

2436* |