If you want to know more information about our machine , please sent email to zhengzhouyuxi@yuximachine.com, we will give you the most professional reply at first time!

Introduction

Coal gangue dryer can be used for the production of low calorific value gas for power generation. It can recyle coal and pyrite and make building materials. Coal gangue can be used to sinter lightweight aggregate and make ceramic, it is also a good soil conditioner. After self-ignition, the coal gangue can be used for grass planting, which can beautify the environment.

Working Principle

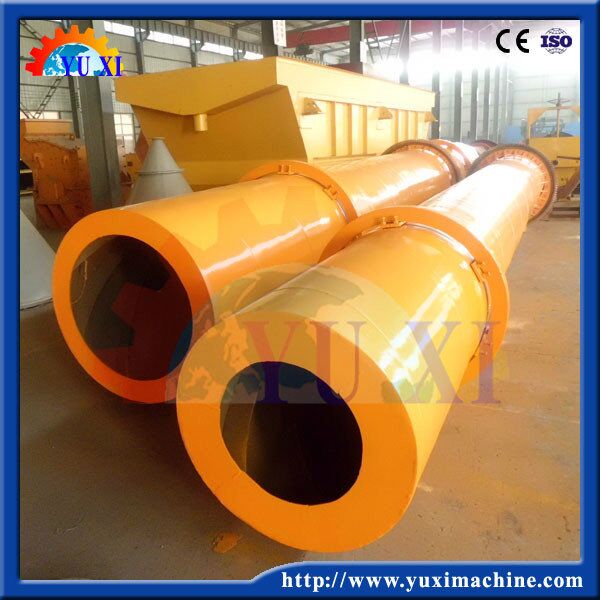

Coal gangue dryer machine is mainly consisted of the heat source, feeding machine, rotary drum, discharging machine, induced draft fan, tripper and power distribution cabinet.

The mineral are conveyed to silo by belt conveyor or bucket elevator, and transported to the feed end by the feeder of silo. To feed the material from the higher end and the heat carrier enter from the lower end. As the cylinder rotates, materials move forward to the lower side by the gravity. So that the wet raw material being dried by the heat directly or indirectly.

Flow Chart Of Process Operations

.jpg)

Features

1. Materials final moisture should be ensured below 0.5%.

2. The dryer cylinder self-insulation thermal efficiency is up to 80%.

3. The fuel for coal gangue dryer can be applicable for coal, oil, gas, etc.

4. The coal gangue drying machine can easily control the final moisture indicators according to user requirements.

5. The outlet temperature is low, dust removal equipment has long service time.

Technical Parameters

Model(m) Rotate Speed(r/min) Gradient(%) Inlet Air Temperature(℃) Capacity(t/h) Weight(t) Ф0.8×8 3-8 3-5 ≤700 0.8-2.0 3.5 Ф0.8×10 3-8 3-5 ≤700 0.8-2.5 4.5 Ф1.0×10 3-8 3-5 ≤700 1.0-3.5 5.6 Ф1.2×10 3-8 3-5 ≤700 1.8-5 14.5 Ф1.2×12 3-8 3-5 ≤700 2-6 14.8 Ф1.5×12 2-6 3-5 ≤800 3.5-9 17.8 Ф1.8×12 2-6 3-5 ≤800 5-12 25 Ф2.2×12 1.5-6 3-5 ≤800 6-15 33 Ф2.2×18 1.5-6 3-5 ≤800 10-18 53.8 Ф2.2×20 1.5-6 3-5 ≤800 12-20 56 Ф2.4×20 1.5-5 3-5 ≤800 18-30 60 Ф3×20 1.5-5 3-5 ≤800 25-35 78 Ф3×25 1.5-5 3-5 ≤800 32-40 104.9