If you want to know more information about our machine , please sent email to zhengzhouyuxi@yuximachine.com, we will give you the most professional reply at first time!

Introduction

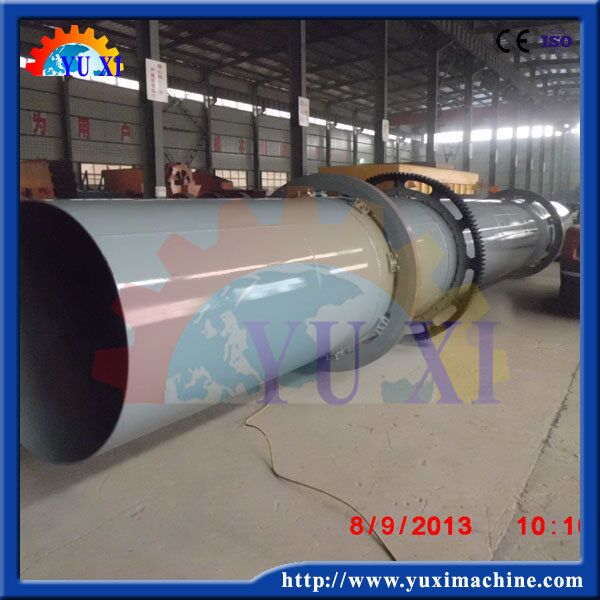

Forage dryer is not only capable of processing forage, but also can effectively dry slag, limestone, coal, clay and other materials, widely used in building materials, metallurgy, chemical industry. It has a strong adaptability of the materials, polular among customers .

Currently, pomace and pulp kind forage raw materials are from brewing, sugar, non-staple food processing and other industries, mainly including vinasse, bean dregs, bagasse, etc. As many of them are wasted, Yuxi Machine designs and develops forage drying production lines with different features according to different raw materials. So that the forage materials can be better for our use. Besides, the forage dryer is with easy operation, high yield, low energy consumption and higher cost performance.

Working Principle

The raw materail enters into the forage dryer by conveyor. There are many lifting plates inside the forage dryer, which will raise up the raw materail, so that the hot air and raw material will be totally contacted. The head of forage dryer have furnace, which will provide the heat for the drying. And there’s a fan at the end of the dryer, which can absorb the heat into the dryer, thus it can dry the forage and take the moisture out. Finally, the dried materails with moisture content around 12% are discharged and conveyed away by conveyor.

.jpg)

Features

1. It has strong anti-overload, high degree of mechanization, large production capacity, continuous operation.

2. Excellent and simple structure, with smooth and easy operation.

3. The forage dryer has less failure, low maintenance cost, low power consumption, good uniformity of drying product.

4. The material is heated quickly and evenly and fully.

5. The cooling process make the dried material temperature approach ambient temperature, which is conducive to storage and transportation.

6. The new type feeding and discharging devices put an end to the feed blockage, discontinuous, uneven, and returning materials phenomena, reducing the load of the dedusting system.

7. The operating parameters can be changed depending on the material properties, so that the material in the dryer cylinder body can form a stable full cut fabric curtain, the quality of heat exchange more fully.

Technical Parameters

Model(mm) Capacity(t/h) Feeding Moisture(%) Discharging Moisture(%) Manpower Host Power (kw) Fuel Calorific Value (kcal/kg) Water Evaporation Quantity (t) Φ1200x10000 1-1.5 65±5 ≤10 3 7.5 ≥6000 0.61 Φ1500x12000 2-4 65±5 ≤10 3 11 ≥6000 1.32 Φ1500x15000 2.5-5 65±5 ≤10 3 15 ≥6000 1.53 Φ1500x18000 5-8 65±5 ≤10 3 15 ≥6000 1.83 Φ1800x18000 8-12 65±5 ≤10 3 18.5 ≥6000 3.61