If you want to know more information about our machine , please sent email to zhengzhouyuxi@yuximachine.com, we will give you the most professional reply at first time!

Introduction

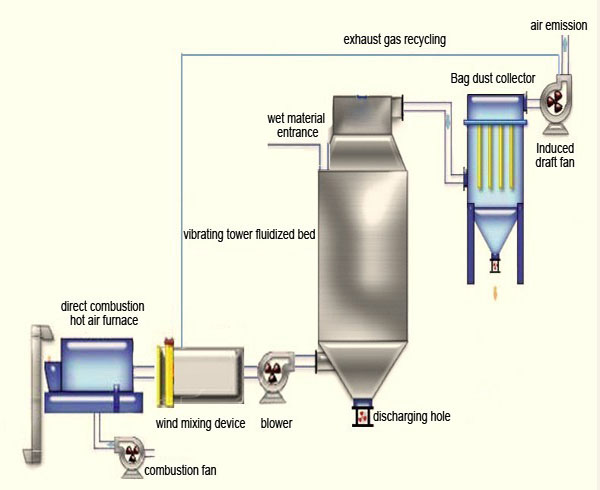

Airflow dryer use airflow instant drying principle, with the features of strong drying strength, short drying time, low energy consumption, easy operation, good product quality and so on. The materials after drying by airflow dryer have advantages of clean appearance, glossy, high fineness, moisture stability, low impurity pollution, etc.

Airflow drying machine is suitable for drying powdery, slice and heat-sensitive materials in starch, rice flour, food, medicine, chemical and other industries. Use of this equipment with minimum investment, minimum power consumption, minimal manpower and space, the fastest speed, to obtain the best economic benefit.

Feature

● Strong drying strength: Since the air speed of airflow dryer is high, the materials are in a good dispersion in the gas phase. And all surface of materis can be used as the drying effective area. Therefore, limited drying area is greatly increased. Meanwhile, since the dispersion and agitation during the drying, gasification surface constantly updated, the heat transfer process has strong strength.

● Short drying time: the material and the air contact time is very short, drying time is generally between 0.5 to 5 seconds. for heat-sensitive or low melting point materials, there will be no overheating or decomposition to affect their quality.

● High thermal efficiency: air-drying adopts material and gas flow co-current operation, material and air temperatures can reach a reasonable state from beginning to end, drying time is short, thus the used drying temperature can be higher.

● Airflow drying machine has a wide application, high yield, simple structure, small covering area, low investment and maintenance costs.

● Hot air source: oil furnace, gas stove, coal stove, steam heat exchanger.

Technical Parameters

Model Diameter(mm) Moisture Evaporation(kg/h) Power(kw) Covering Area(㎡) YX25 250 30~80 13 15 YX30 300 70~150 16.5 20 YX35 350 100~200 22 25 YX40 400 120~250 29 25 YX50 500 200~400 50.2 30 YX60 600 300~600 68.2 40